Specifically designed for

Two-Photon Polymerization

Nanoscribe IP Resins are established standard materials for high-resolution microfabrication. Submicrometer resolution and shape accuracy as well as easy handling are key features of these negative-tone resins.

Choose the photoresins best suited to your applications. Benefit from submicron features, overhanging elements, optical-quality surfaces, high-speed mesoscale fabrication, biocompatibility or high refractive index.

IP Resins are highly-efficient printing materials and an essential element of Nanoscribe’s Microfabrication Solution Sets. The printer software offers advanced recipes optimized for different photoresins and applications. They make the 3D printing workflow straightforward and speed up the design iteration cycles for scientific and industrial use cases ranging from biomimetic surfaces, microoptical elements to mechanical metamaterials and 3D cell scaffolds.

Nanoscribe 2PP photoresins

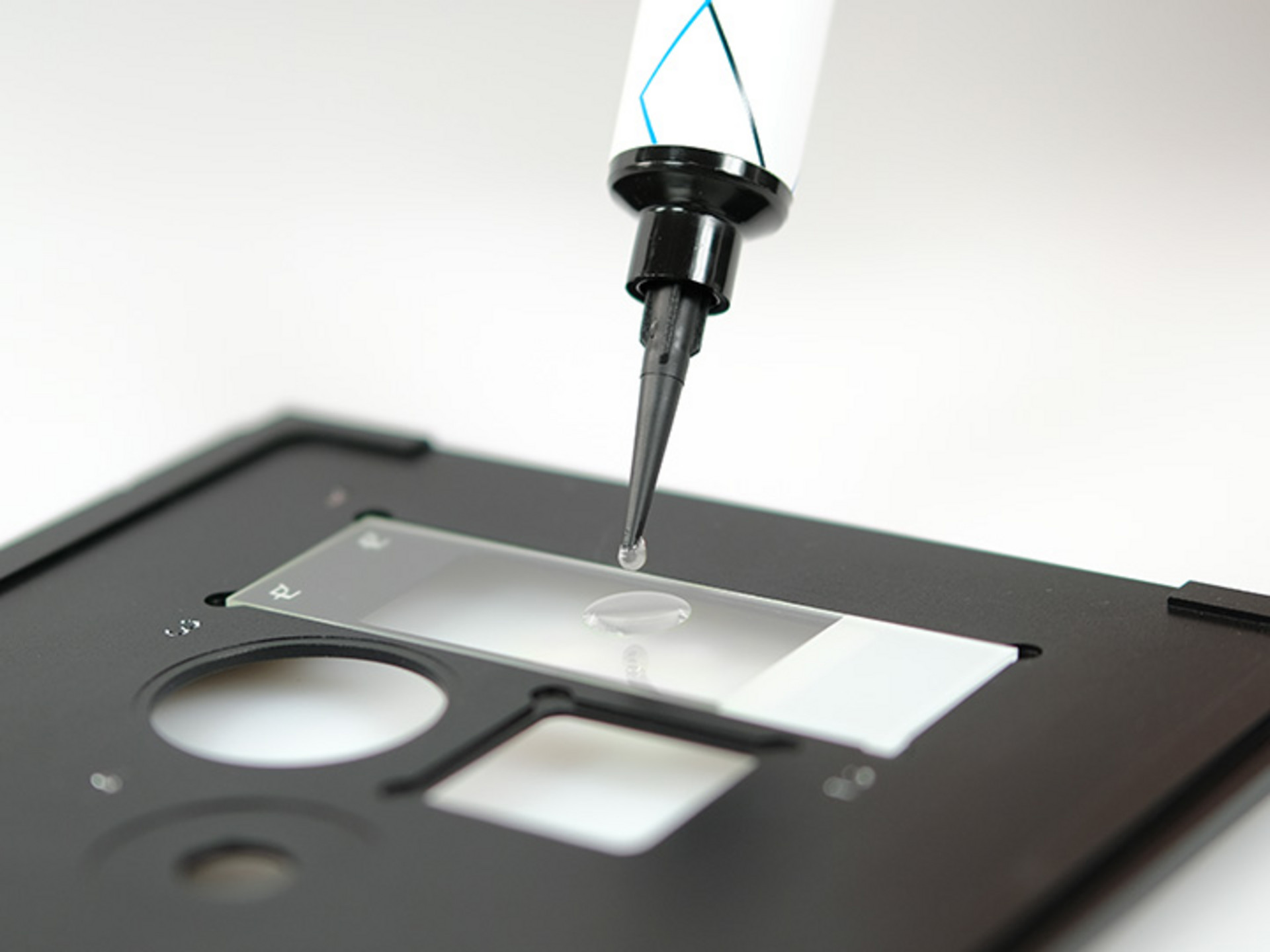

Our photoresins are available in lightproof and resealable cartridges. Take advantage of convenient dosing by hand or automatic dispensing onto substrates, wafers, chips and other microparts – precise and bubble-free.

We provide a product line of negative-tone resins, called IP Photoresins. They are optimized for Two-Photon Polymerization (2PP) and feature remarkable properties required in high-precision additive manufacturing:

- Minimum feature sizes of typ. 160 nm

- High-speed microfabrication

- Excellent adhesion to various substrates

- Optimized mechanical stability and excellent shape accuracy

- Straightforward handling and easy processing

- Neither spin-coating nor post-exposure bake required

Our photoresins are optimized for its use with Nanoscribe Photonic Professional GT2 3D printer, Quantum X maskless lithography system and high-performance 3D printer Quantum X shape.

Professor Giovanna Brusatin, University of Padova

Nanoscribe IP Resins are really efficient. With IP-Dip we produce molds for replication, with IP-S micro nozzles. With the Photonic Professional GT we also use other materials as hydrogels or siloxane.

Explore details on

materials and processes

| Resin | Advantages | Possible applications |

| New IP-PDMS | 2PP printing of soft, flexible and highly elastic structures | Material engineering, life sciences, cell and tissue engineering, microfluidics, microelectromechanical systems (MEMS) |

| New IP-n162 | High refractive index material with n=1.62. Photoresin with low absorption in the infrared range. Well suited material for direct printing and prototyping of 2.5D and 3D microstructures. | Refractive microoptics in 3D and free space microoptics for integrated photonics |

| IP-Visio | Biocompatible, non-cytotoxic according to ISO 10993-5 / USP 87. Low autofluorescence for cell microscopy. | Multi-cell scaffolds, tissue engineering, biomedical devices, life sciences |

| IP-Q | High-speed fabrication of millimeter-sized objects. Designed for Dip-in Laser Lithography (DiLL) | Biomedical engineering, mechanical components, micro rapid prototyping |

| IP-S | Biocompatible, non-cytotoxic according to ISO 10993-5 / USP 87. Smooth surfaces for micro- and mesoscale fabrication with optical-quality surface roughness and shape accuracy. Designed for DiLL. | Mechanical metamaterials, microoptics, integrated photonics, microfluidics, cell scaffolds |

| IP-Dip2 | Finest submicron features and high aspect ratio structures. Designed for DiLL. | Photonic metamaterials, diffractive optical elements, microoptics, micromechanics & MEMS, integrated photonics |

| IP-G | Complex 3D designs, e.g., overhanging elements. Submicron features and low shrinkage. Designed for oil immersion configuration. | Overhanging elements in biomimetics, photonics, microrobots |

| IP-L | Biocompatibility, non-cytotoxic, evaluated by our customers, partly under stricter requirements than ISO 10993-5. Submicron features and low shrinkage. Designed for oil immersion configuration. Compatible with DiLL. | Plasmonics, photonic and biomimetic surfaces |

Nanoscribe IP Resins are available for Nanoscribe systems only. Upon request we also provide the following IP Photoresins without photoinitiator: IP-S and IP-Q. Contact us for more information.

| Properties | Refractive index 1 @589 nm, 20 °C | Young‘s modulus 1 [GPa] | Biocompatibility | Classification / Print set |

| IP-Q2 | 1.513 | 3.1 | yes3 | Universal / LF |

| IP-S2 | 1.515 | 2.1 | yes4 | Universal / MF |

| IP-Dip2 | 1.547 | 1.5 | yes3 | Universal / SF |

IP-L | 1.519 | 4.7 | yes5 | Universal / SF |

| IP-G | 1.515 | 3.4 | n/a | Sol-gel / SF / MF |

| IP-PDMS | 1.450 | 0.015 | yes4 | Functional / MF |

| IP-n162 | 1.622 | n/a | yes4 | Functional / MF |

| IP-Visio | 1.511 | n/a | yes4 | Functional / MF / LF |

1 measured on 3D printed or UV-cured structures; results depend on the printing conditions and geometry

2 upon request available without photoinitiator

3 No cytotoxic effect but a slight reactivity according to ISO 10993-5

4 Non-cytotoxic according to ISO 10993-5

5 Non-cytotoxic, evaluated by our customers, partly under stricter requirements than ISO 10993-5

Print Sets: LF – Large Features, MF – Medium Features, SF – Small Features

The microfabrication devices from Nanoscribe are designed as open systems, suitable for a broad selection of materials. The variety of materials extends further to third-party UV-curable photoresists, hydrogels or nanoparticle composite resins, and custom-made materials.

To satisfy the needs of material developers for testing new resins, a variety of materials and processes allow optical, mechanical, electrical, chemical and biological properties to be tuned as needed, e.g., in optics, photonics or biomedical engineering.

Post-print processes, e.g., casting, atomic layer deposition (ALD), chemical vapor deposition (CVD) or galvanization, allow modification of the 3D printed structures and permit the inclusion of further materials including ceramics, metals, glass or other plastics.

Third-party photoresists

- SU-8 – negative-tone, epoxy-based resists

- AZ ® photoresists – positive-tone resists

- ORMOCER ® polymers – inorganic-organic hybrid polymers

Custom-made materials

- Hydrogels - e.g., degradable resins

- Composite materials

- Liquid-crystal elastomers

Precise and clean dispensing of printing materials

Our photoresins are available in lightproof and resealable cartridges. Take advantage of convenient dosing by hand or automatic dispensing onto substrates, wafers, chips and other microparts – precise and bubble-free. Further advantages:

- Improved cleanliness

- Better handling and dispensing

- High-yield dispensing

Interested in our IPX Photoresins

specifically designed for Quantum X systems?

Explore the IPX Photoresins and how you can make the most of the speed, precision, and performance of the Quantum X platform.