How can light fields be tailored to generate discrete high-resolution focus points on separate image planes? A team of researchers at the Leibniz Institute of Photonic Technology in Jena has achieved a groundbreaking success in the manipulation of light fields. Innovative fiber-compatible holograms were 3D-printed to create complex multi-foci intensity patterns in 3D, with finely tuned relative phases between individual foci. Excitingly in dual focus mode two foci can still be separated, although their distance is designed to be below Abbe’s diffraction limit of light. The introduced concept paves the way for phase-controlled 3D digital holography over remote distances, which has enormous application potential in fields such as quantum technology, life sciences, bioanalytics, and telecommunications.

Fiber-based holograms for high-resolution

multi-foci intensity patterns

Diffractive optical elements (DOEs) and holograms can manipulate light waves in manifold and fascinating ways. It is like being able to paint with light, creating specific patterns of brightness and changing how the light waves are aligned. While DOEs often create 2D patterns on a single image plane, holograms are capable of producing more complex, 3-dimensional representations with multiple focal planes.

Besides their aesthetic appearance, tailored light fields with spatially controlled intensity and phase distribution have great potential for many applications, including various illumination scenarios for microscopy, optical trapping, and parallelized 3D nanoprinting, opening up new possibilities in nanophotonics, fiber optics and waveguide technology, as in any field requiring precise excitation of higher-order optical resonances.

Two-Photon Polymerization for 3D nanoprinted holograms

In general, phase controlling holograms are widely accepted to produce multi-focal light patterns more efficiently than amplitude masks. However, direct engineering of the phase itself remains challenging, and in most scenarios, only the intensity distribution is known. Researchers at the Leibniz Institute of Photonic Technology (Leibniz IPHT) in Jena, Germany, addressed this challenge by utilizing Nanoscribe’s Two-Photon Polymerization (2PP) technology for the 3D Microfabrication of hologram optics to create complex patterns of multiple focal points. As a key feature, the fabricated holograms not only modulate the intensity distribution, but also control the relative phase of each individual spot. By manipulating the individual phase of each focal point and the resulting interferences, they were able to study the interaction between individual foci and make a remarkable observation about the resolution limit of two individual foci.

Furthermore, the researchers used their new design approach to 3D print a hologram on a single-mode optical fiber, generating distributions of approximately 200 individual focal points in two separate image planes.

At the limit of light resolution

The developed holograms build upon the Huygens-Fresnel principle, a fundamental concept in wave optics that describes how a wavefront propagates through space. It states that every point on a wavefront acts as a source of spherical secondary wavelets, and the superposition of these secondary wavelets gives rise to the wavefront at a later time. By extending this theory the interference-based approach allows control over both intensity and phase of individual focal points in an array of spots distributed in three spatial directions. By modulating the phase of two adjacent focal points in their simulated hologram designs the researchers made a fascinating observation: despite being designed to lie below the resolution limit of light, the two foci could still be distinguished and separated.

To prove their simulations to be correct, Nanoscribe's 3D Microfabrication comes into play. The team in Jena 3D-printed holograms with a designed diameter of 60 µm and smallest submicrometer features. They found a perfect match between their simulations and experimental results, underpinning the excellent precision of 2PP-based 3D Microfabrication.

3D-printed multi-foci holograms on optical fibers

As a highlight of their research project the scientists used their new design approach to develop a complex hologram, providing 192 individual focus points in two separate image planes. While the individual focus points on the first plane showing the logo of the IPHT institution, in the second plane reveals the institutions lettering (“IPHT”). The challenging design with submicrometer feature size was printed with highest precision on the facet of a customized single mode fiber for red light at 637 nm.

3D Printing on fibers with nanoprecision alignment

The Jena researchers utilized Nanoscribe’s most mature scientific microfabrication platform, the Photonic Professional GT2, equipped with a 63x objective lens, to achieve the precision and submicron feature size required for their study. However, they encountered challenges when printing on fibers, such as substrate tilt, which they resolved by printing a 3 µm base layer beneath the hologram.

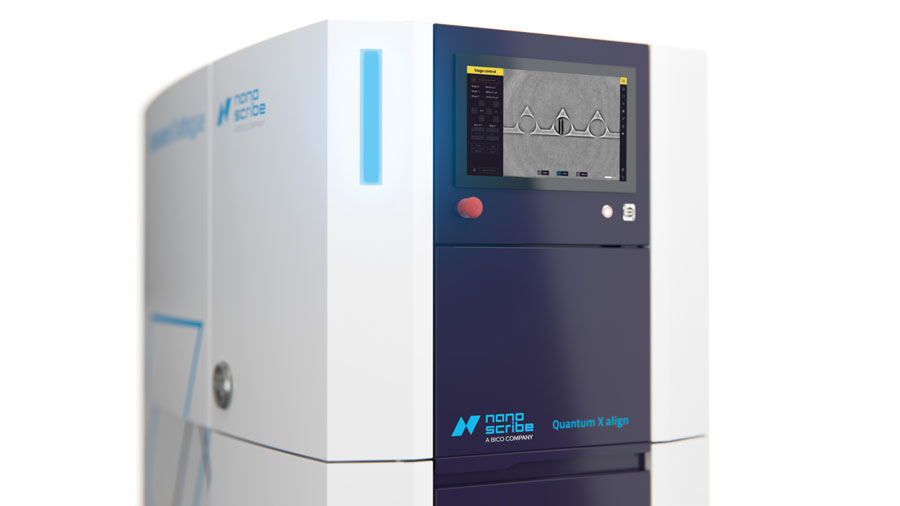

Recognizing the growing demand for aligned printing on optical fibers and photonic chips, Nanoscribe has introduced the Quantum X align, a high-resolution 3D printer which incorporates Aligned 2-Photon Lithography A2PL® for nanoprecision alignment on optical fibers and photonics chips and features such as automatic tilt measurement and compensation. In addition, hardware enhancements like a fiber substrate holder and fiber core illumination unit would undoubtedly be valuable assets for reliable fiber core identification, thereby facilitating further advances in fiber holography.

If you want to read more about this research project, you can find the complete scientific publication here: Fiber-based 3D nano-printed holography with individually phase-engineered remote points | Scientific Reports (nature.com)

This and further scientific publications on more than a thousand research projects from Nanoscribe customers and system users can be found in a powerful database with a keyword search in the Premium resources section. Register for free to see for yourself the potential of Nanoscribe’s 3D Microfabrication technology for innovative applications and fundamental innovations in many areas, and to evaluate its suitability for your project.

Video information

Phase hologram printed by Two-Photon Polymerization (2PP) on the facet of an optical single-mode fiber. This on-fiber printed hologram generates two separate multi-focus patterns distributed on two consecutive image planes. On the first image plane, the logo of the Leibniz Institute of Photonic Technology appears, and on the second image plane, the acronym of the institute IPHT is spelled out. On the right side of the image, a SEM image of the hologram and the measured focus distributions are shown.