About Nanoscribe

The medium-sized company develops and produces 3D printers and grayscale lithography systems as well as specially developed printing materials and application-specific solutions for various microfabrication applications. The specialist for additive manufacturing of high-precision structures and objects on the nano-, micro- and mesoscale was founded in 2007 as a spin-off of the Karlsruhe Institute of Technology (KIT) and is part of the BICO Group since June 2021. More than 4,000 users and operators at top universities and innovative companies worldwide benefit from the groundbreaking technology and application tailored solutions for 3D Microfabrication. Nanoscribe has created its strong market leading position through high quality engineering and agility to continuously develop its products to meet customers’ high expectations.

About BICO

Founded in 2016, BICO (formerly CELLINK) is the leading bio convergence company in the world. By combining different technologies, such as robotics, artificial intelligence, computer science, and 3D bioprinting with biology, we enable our customers to improve people’s health and lives for the better.

The company has a focus on developing technologies that will advance Health 4.0 Next Generation Core Industry Ecosystems that enable tissue engineering, diagnostics, multiomics, and cell line development. BICO’s technologies enable researchers in the life sciences to culture cells in 3D, perform high-throughput drug screening and print human tissues and organs for the medical, pharmaceutical, and cosmetic industries. We create the future of health.

The Group’s instruments in the field amounts to 25,000, including all the top 20 pharmaceutical companies, are being used in more than 65 countries, and have been cited in more than 9,500 publications. BICO is listed on Nasdaq Stockholm under BICO. www.bico.com

Captions

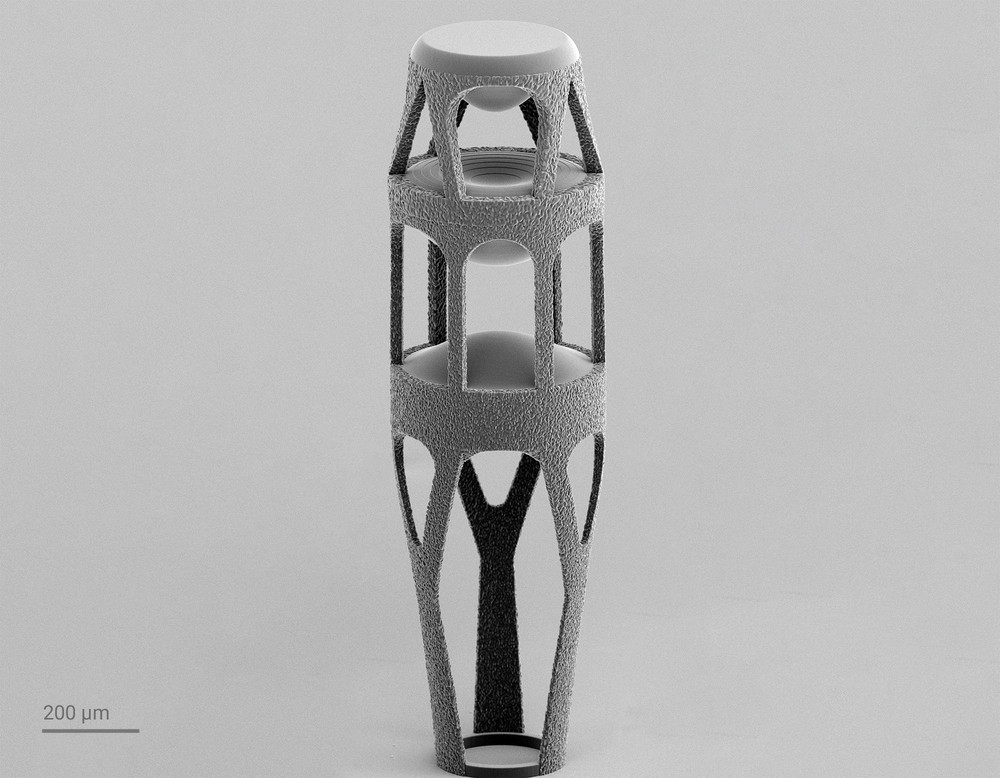

Img. 1: With its exceptional print quality and incredible speed, 3D printing by 2GL® is breaking new ground and opening up previously inaccessible applications. These high-precision optics developed for a miniature endomicroscope are a perfect example: All three freeform lenses have optical-grade surfaces on the top and bottom, integrating diffractive and refractive elements in one optical system and are printed in one pass. Manufactured by Nanoscribe, lens designed by Printoptix.

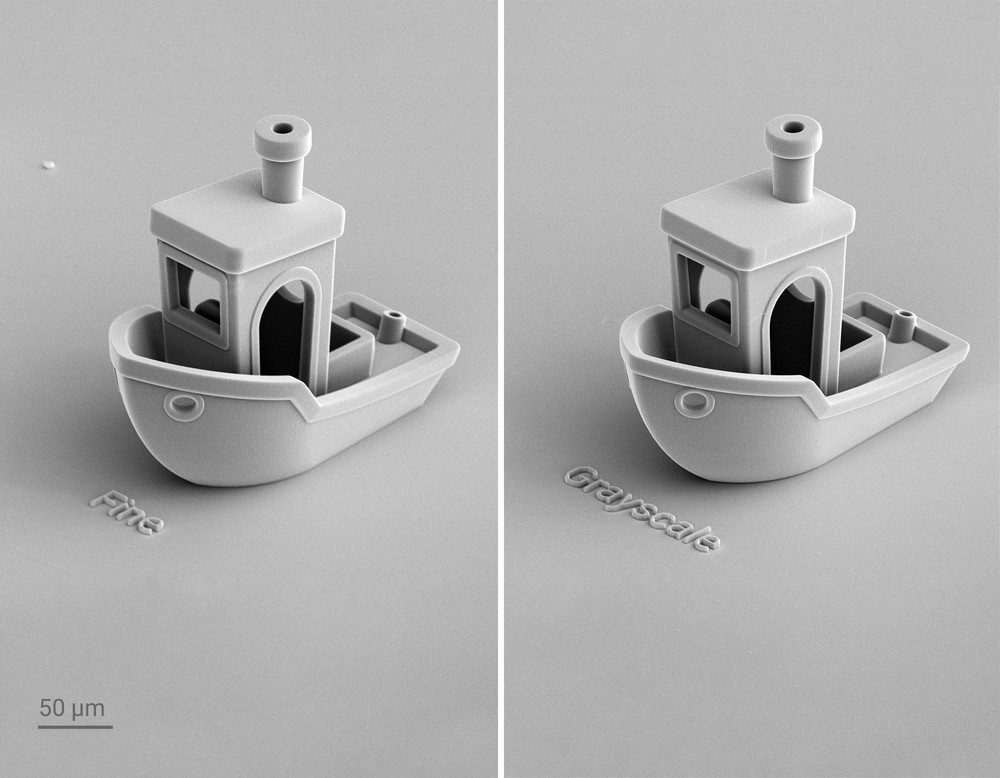

Img. 2: 3D printed Benchy boat split into two parts. Left part is 3D printed by 2GL. Right part is made with conventional 2PP-based 3D printing. Both parts are printed at exactly the same slicing distance, resulting in identical printing time. However, using 2GL, there are no slicing steps and the real shape of the Benchy boat is revealed, free from any voxel-related distortion.

Img. 3: Speed comparison of a Benchy boat 3D printed with a very competitive 2PP system (left) and with 3D printing by 2GL (right). To obtain the highest possible print quality, the slicing distance of the 2PP printed boat is set to 0.1 µm (“Fine”). In contrast, the same object is 3D printed by 2GL (“Grayscale”) with a significantly coarser slicing of 1 µm, resulting in a print time reduced by a factor of 10.

Img. 4: This microscope image showcases the microendoscope lens, perfectly aligned on the facet of an optical fiber and 3D printed by 2GL. The optical brilliance exhibited by the top lens serves as a testament to the exceptional quality of the print.

Manufacturing by Nanoscribe, lens design by Printoptix.

Img. 5: Close-up of the stacked lens system, showing the freeform top lens and the central hybrid lens with its diffractive element. 3D printing by 2GL enables printing of optically smooth surfaces without any slicing steps and with sharp edges as required for the diffractive element. Manufacturing by Nanoscribe, lens design by Printoptix.

Right of use and media relations

Our image may be used free of charge for editorial purposes. Please state the source as follows: "Image: Nanoscribe, www.nanoscribe.com". The image must not be used for commercial purposes or passed on to third parties.

In case of questions or if you would like to be added to our press mailing list, please do not hesitate to contact Johannes Lang, media@nanoscribe.com.

Stay up to date with our latest press releases about Nanoscribe and the world of 3D Microfabrication. Directly get in touch with us to discuss further press activities: Media relations